Imvelaphi

Kwakhutshwa inguqulelo entsha ye-UL 1642. Enye indlela yovavanyo lwempembelelo enzima yongezwa kwiiseli zesingxobo. Iimfuno ezithile zezi: Kwiseli yesingxobo esinomthamo omkhulu kune-300 mAh, ukuba ukuphumelela uvavanyo olunzima lwempembelelo aluphumelelanga, banokufakwa kwiCandelo le-14A lovavanyo lwentonga ejikelezayo.

Iseli yesingxobo ayinayo imeko enzima, ehlala ikhokelela ekuqhekekeni kweseli, ukwaphuka kwempompo, ubutyobo obubhabha ngaphandle kunye nomnye umonakalo omkhulu obangelwa kukungaphumeleli kuvavanyo lwempembelelo enzima, kwaye kwenza kube nzima ukubona isekethe emfutshane yangaphakathi ebangelwa sisiphene soyilo okanye isiphene senkqubo. . Ngovavanyo olujikelezileyo lwentonga, iziphene ezinokwenzeka kwiseli zinokubonwa ngaphandle kokonakalisa isakhiwo seseli. Uhlaziyo lwenziwa kunye nale meko kuqwalaselwa.

Ukuhamba kovavanyo

- Isampulu ihlawuliswa ngokupheleleyo njengoko kucetyiswa ngumvelisi

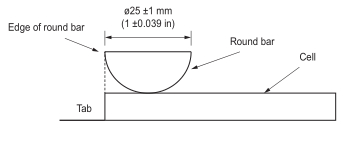

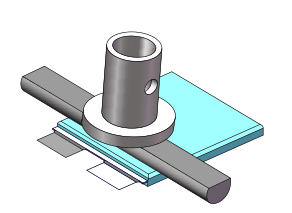

- Beka isampuli kwindawo ethe tyaba. Beka intonga yentsimbi engqukuva kunye nobubanzi be-25±1mm phezu kwesampulu. Umphetho wentonga kufuneka ulungelelaniswe nomgca ophezulu weseli, kunye ne-axis ethe nkqo i-perpendicular kwithebhu (FIG. 1). Ubude bentonga kufuneka bube ubuncinane be-5mm ububanzi kunomphetho ngamnye wesampuli yokuvavanya. Kwiiseli ezinetabhu ezilungileyo nezingalunganga kumacala ahlukeneyo, icala ngalinye lethebhu kufuneka livavanywe. Icala ngalinye lethebhu kufuneka livavanywe kwiisampuli ezahlukeneyo.

- Umlinganiselo wobunzima (ukunyamezela±0.1mm) kwiiseli ziya kwenziwa phambi kovavanyo ngokuhambelana neSihlomelo A se-IEC 61960-3 (Iiseli zesibini kunye neebhetri eziqulethe i-alkaline okanye ezinye i-electrolyte ezingenayo i-acidic-iiseli ze-lithium eziphathwayo kunye neebhetri-Icandelo 3: I-Prismatic kunye ne-cylindrical lithium yesibini iiseli kunye neebhetri)

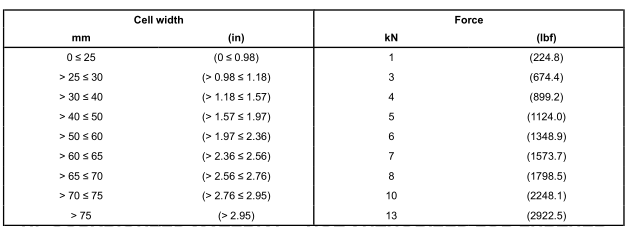

- Emva koko uxinzelelo loxinzelelo lusetyenziswa kwintonga ejikelezileyo kwaye ukufuduka kwicala elithe nkqo kubhalwe (FIG. 2). Isantya esihambayo sepleyiti yokucinezela asiyi kuba sikhulu kuno-0.1mm / s. Xa ukuguqulwa kweseli kufikelela kwi-13±I-1% yobunzima beeseli, okanye uxinzelelo lufikelela kumandla aboniswe kwiThebhile 1 (ubukhulu obuhlukeneyo beeseli buhambelana namaxabiso ahlukeneyo amandla), yeka i-plate displacement kwaye uyibambe i-30s. Uvavanyo luyaphela.

- Akukho mlilo okanye ukuqhuma kweesampuli.

Uhlalutyo lovavanyo

- Ukukhethwa kwendawo ye-extrusion: indawo ye-pali ye-pali yindawo ebuthathaka yeseli yesingxobo, kwaye indawo ye-tab inoxinzelelo olukhulu xa icudiswa. Izizathu zezi:

a) Ubungakanani bobungakanani obungalinganiyo (ubukhulu obungalinganiyo phakathi kwethebhu yepali kunye nento esebenzayo ejikelezileyo ikhokelela kuxinzelelo olungalinganiyo losasazo)

b) Amanqaku e-Welding kwindawo ye-tab (usasazo loxinzelelo kwindawo ye-weld kunye ne-non-weld point)

- Ukukhethwa kwentonga ejikelezayo: Ububanzi bentonga ejikelezayo yi-25mm. Eli xabiso likhethwa ukugubungela yonke indawo ye-pali tab kwiseli (ingakumbi indawo egquma i-pole tab solder joint).

- 13±1% deformation: Okwangoku, obona bunzima beeseli kwimarike yi-2mm. Ngenxa yempembelelo yokuvalwa kwebhetri okanye inkqubo yokupakisha, ubuncinane i-8% yohlobo oluguquguqukayo luyafuneka ukunyanzeliswa kwi-pole tab solder joint, kodwa iya kukhokelela ngokuthe ngqo ekuqhekekeni kwe-electrode ukuba uhlobo oluguquguqukayo lukhulu kakhulu. Ixabiso le-13±I-1% ikhethwe kolu hlaziyo, ngokubhekiselele kwi-middle variable 15% kwi-extrusion test kwi-IEC 62660-3.

- Ukhetho lwesampulu: Kufuneka kuqatshelwe ukuba olu vavanyo lwenzelwe kuphela iiseli zesingxobo esinomthamo omkhulu kune-300mAh kwaye ezingakhange zibethwe zizinto ezinzima. Iisampulu ezi-5 ziyafuneka. Iiseli zeCylindrical okanye zeprismatic kunye neeseli zepouch ezibethelwa zizinto ezinzima't iyimfuneko ukuba ithathelwe ingqalelo kolu vavanyo.

Isishwankathelo

Uvavanyo olutsha olujikelezayo lwe-extrusion luhluke kuvavanyo lwe-extrusion yasekuqaleni ye-UL 1642. Uvavanyo lwe-extrusion yasekuqaleni kukusebenzisa i-flat extrusion, kwaye usebenzise i-13kN force eqhubekayo ngaphandle kokubamba ixesha. Isebenza kuzo zonke iintlobo zeeseli. Olu vavanyo luhlola amandla omatshini weseli ngokubanzi (kubandakanywa necala) kunye nokukwazi ukumelana noxinzelelo lomatshini; ngelixa i-extrusion yentonga ejikelezayo ivavanya kuphela inxalenye yeseli, indawo encinci ye-indenter iya kwenza uxinzelelo lwangaphakathi lugxininise, lula ukukhokelela kwisiphaluka esifutshane sangaphakathi. Ngokukodwa, indawo ye-extrusion ikhethwe kwindawo ebuthathaka ye-pole tab welding, enokuthi iphande ngcono ukusebenza kokhuseleko lweseli.

Okwangoku, le ndlela yentonga ejikelezayo iphinda isetyenziswe kuvavanyo lwe-extrusion ye-pouch cell kwi-GB 31241. I-MCM inamava ovavanyo olutyebileyo kulo msebenzi.

Ixesha lokuposa: Nov-16-2022